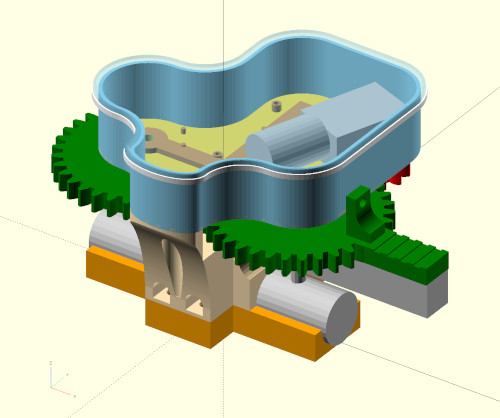

In a project with the Berlin based aid organisation Cadus we wanted to come up with a way to reduce the power consumption of washing machines. Cadus runs multiple field hospitals where it is necessary to wash textiles with high temperatures to ensure a hygienic cleaning. Since electrical power can be a scarce resource in the field, we thought about solutions that would allow the use of solar energy to heat up the water used for washing. As one major constraint, we did not want to modify the washing machines themselves. Our prototype solution consists of a 3-way valve that operates automatically (Fig. 1). The valve is equipped with a flow sensor that can measure the amount of water used by the washing machine. Based on this measurement, the valve uses a robust heuristic to estimate where in the washing program the machine currently is and if the machine will need hot or cold water next. The valve switches then between the hot and cold water source accordingly.

Our design uses only parts that are readily available in most hardware stores and is otherwise 3D printed. The electronics are based on components from the Arduino ecosystem that are readily available, easy to program, and can be easily adapted to similar components if a component is not available. This way, the device is straightforward to build and maintain. You can find a detailed explanation of the project, all CAD files, a bill of materials, and the microcontroller code on my GitHub page.